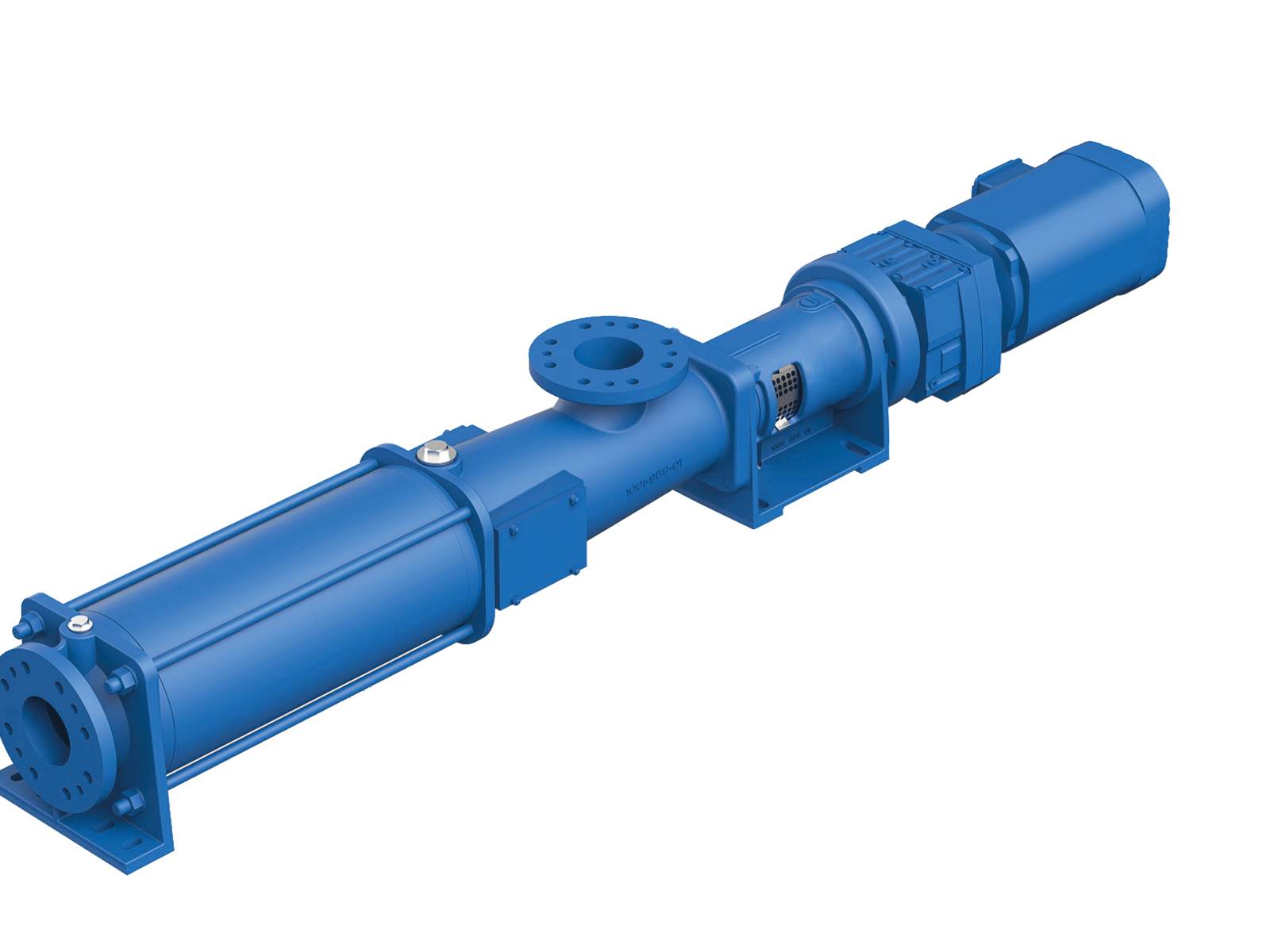

Progressing cavity pump

The progressing cavity pumps are exceptonally well suited for the conveyance of self-flowing liquids; from lower to high viscoity liquids, along with solid-laden solutions. The low pulsation and low shear contribute to the pumps ability convey highly abrasive, sticky or lumpy media as well as alkali and chemical medium with a dry stubstrat content rate of 45%. These are various designs and materials offered for the rotor, stator and the pumps case, even the drive. In this way, the best possible adaptution to customer requirement (pumped medium space, pressure etc.) can be guaranteed. In addition to reliable delivery, the progressive cavity pump is ideal for numerous dosing tasks.

Reliable progressing cavity pumps are typically used in the following sectors:

- Waste water

- Biogas

- Shipping and machine construction

- Paper industry

- Chemical industry

- Food production

- Pharmaceutical industry

GeneraL characteristics

- Very high dosing accuracy

- Up to pulsation-free volume flow

- Large adjustment ranges possible

- Gentle, low-shear conveyance (such as for whole fruits)

- The conveying quantity can be regulated in proportion to the drive speed and remains relatively stable with changing pressures, temperatures and viscosities

Technical specifications

- 0 to 400'000 l/h conveying capacity

- Pressures up to 80 bar

- For thin to compact media from approx. 0.3 to 1'000'000 mPas

- Very high dosing accuracy

- Self-primíng up to 9 m WS

- Temperatures from -30 to 350°C

General applications

- Dosing, conveying, emptying and reversíng

- For up to abrasive, corrosive, gaseous and particle-laden media

Functional principle

Progressing cavity pumps are rotating positive displacement pumps that are used in practically all industrial sectors. The principle is based on a rotor that is asymmetrically shaped to the stator. The rotor rotates eccentrically in the stationary stator. The resulting cavities move spirally from the suction to the discharge side and thus transport the medium with low shear forces. The cavities are constant over the entire delivery, and no turbulence or compressions occur. Thus progressing cavity pumps can deliver thin to stiff media, even loaded with solids or fibres, without any problems, gently and with low pulsation.

Additional information

- Hygiene pump

- Hygiene pump acc. to EHEDG

- Pump with screw conveyor

- Pump with suction nozzles up to DN 400

- ATEX-conform pump available

- Pump can be heated/cooled

Further information and advice

We will be happy to support you using our expert knowledge and our experience to choose the right progressing cavity pump. Please contact us for further information or detailed advice.