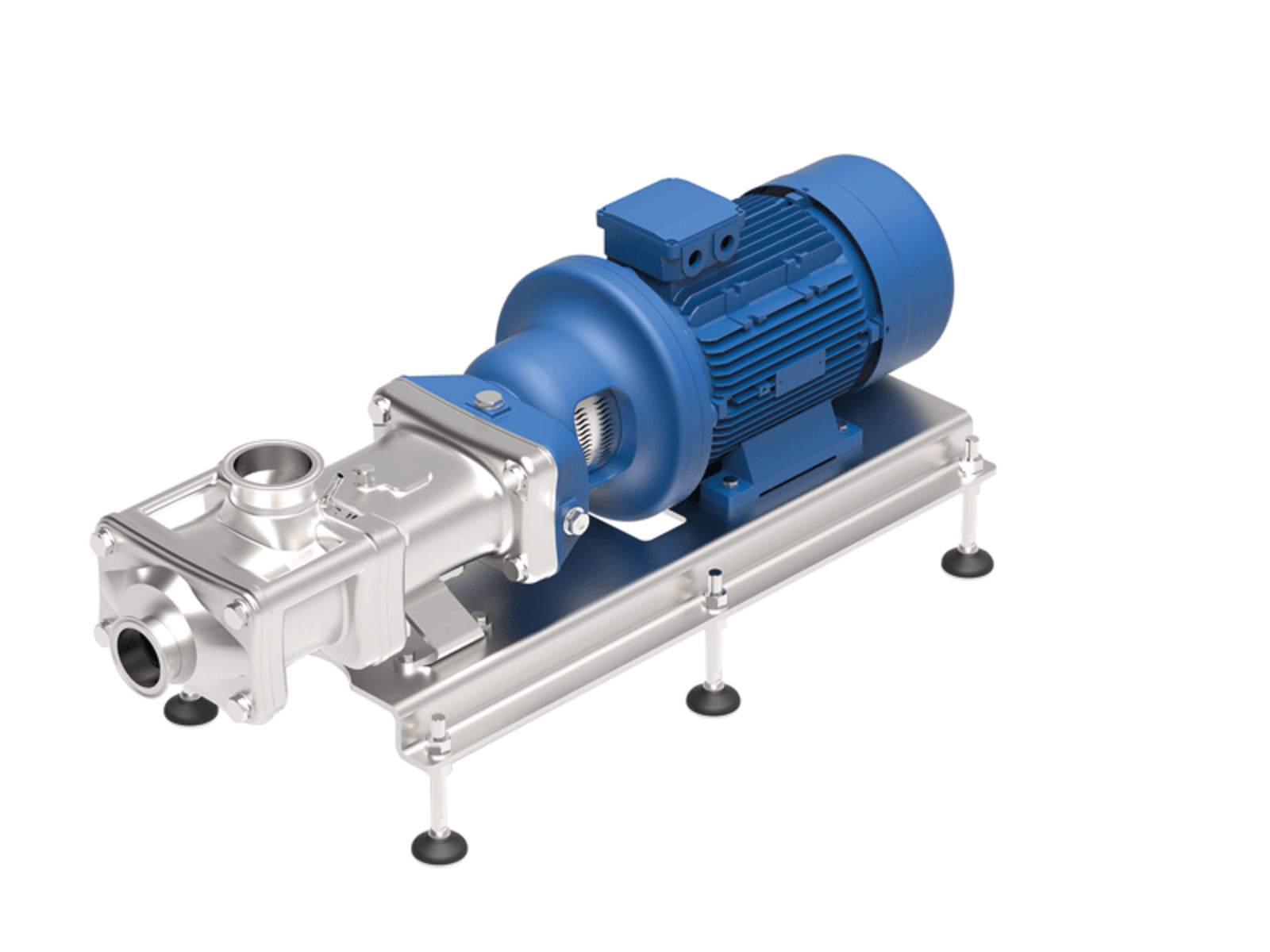

RotoTwin screw spindle pump

Pathogens don't stand a chance! To meet the stringent requirements of the foodstuffs, pharmaceuticals, cosmetics or chemicals industry, companies working in this sector need equipment such as the RotoTwin® screw pump, which was designed to meet the strict EHEDG hygiene requirements.

Two intermeshing rotating feed screws reliably deliver products with high to low viscosity as well as gaseous or volatile products. Due to the axial movement and low acceleration, the RotoTwin® never fails to impress with its powerful suction capability and gentle product delivery. The contactless operation of the feed screws makes the pump safe even when running dry.

Even larger air bubbles in the pipe will not harm the pump. The pump’s ability to reverse the direction of rotation enables the medium to be pumped in both directions, making it possible to use the pump for filling or emptying

General characteristics

- 0 to 200'000 l/h conveying capacity

- Pressures up to 25 bar

- For fluid media from 0.3 to approx. 100'000 mPas

- Suction capacity up to 7 m WS also with high transport volumes

- Limited self-priming

- Temperatures from -10 to 130 "C

- Low-pu lsation conveya nce

- Very easy to clean (CIP, SIP)

- Gentle conveyance

- Dry-running safety (option)

- Large possible adjustment ranges

General applications

- Dosing, conveying, emptying, transferring and reversing

- Up to abrasive, corrosive, gaseous and particle-laden media

- CIP or SIP cleaning possible with the same pump

Additional information

- Pump can be heated/cooled

- Pump built on a carriage with a controller for mobile use