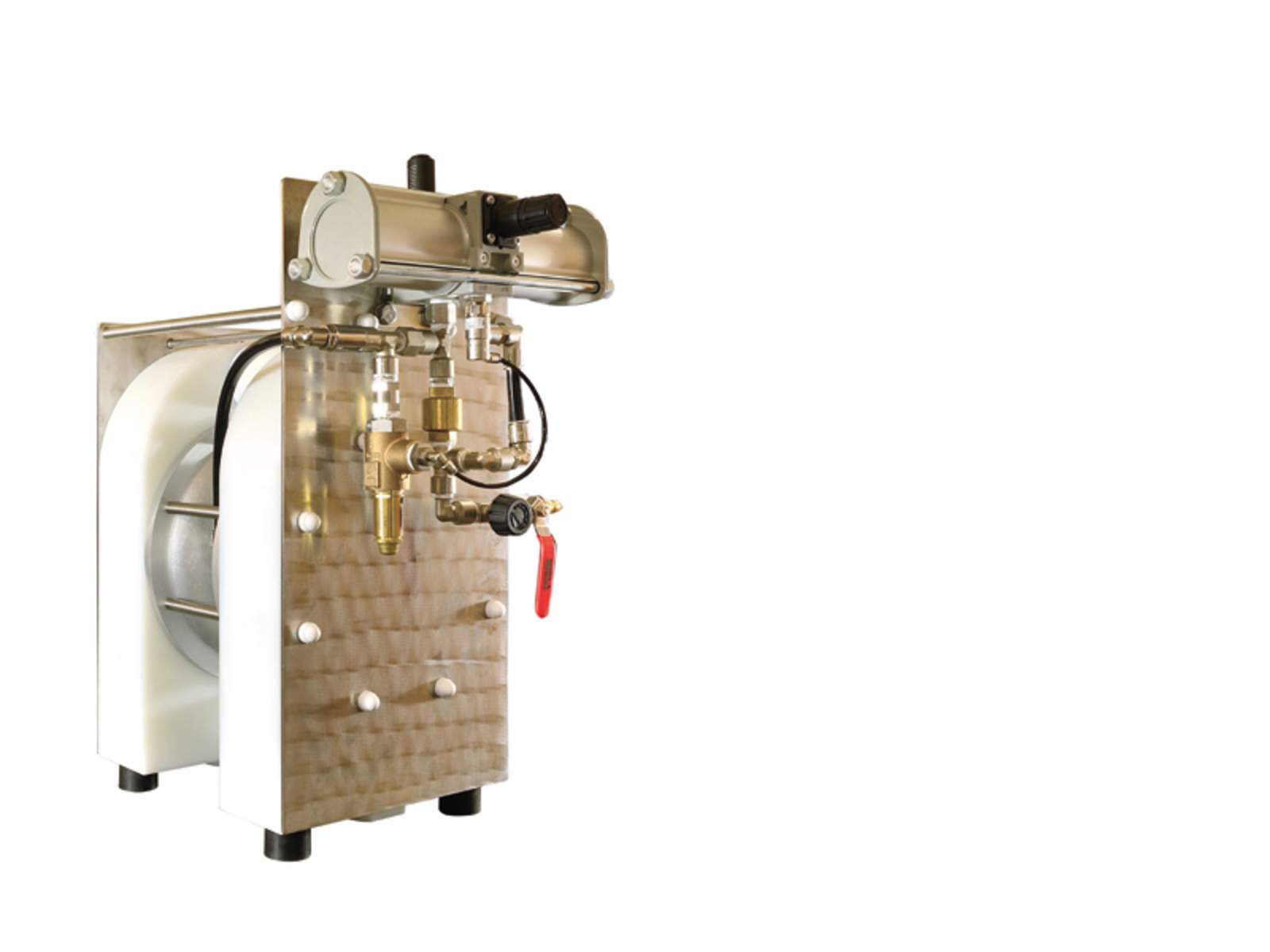

Filter Press Pumps

The compressed air diaphragm pump, which is specially developed for feeding the chamber filter presses, operates completely independently and does not require an additional air vessel, pressure transmitter or speed controller.

Standstill with full filter press

The end of the pressing time is reached when the filter press is filled with solids to such an extent that no more sludge can be taken in. The compressed air drive now ensures that the pump’s delivery rate is zero and that the delivery pressure is at the desired level and compresses the filter cake. This results in excellent dry substance contents. At the end of the pressing time, the pump simply stops.

Very easy to set up

The desired final pressure in the filter press is easily set by the level of air pressure supplied to the pump. At a desired final pressure of 12 bar, the pump must be supplied with 6 bar.

Low air pressure

The pump needs the maximum amount of air only during the filling phase. The fuller the press, the slower the pump works. Thus the air consumption slowly approaches zero as the filtration time progresses.

General properties

Flow rates up to 27,000 l/h

Pressures up to 16 bar

High pressure ratio of up to 1:2

Self-priming

Dry-run resistant

Self-regulating

Further Versions

ATEX-certified pump available

Hygienic pump meeting FDA regulations

Pressure intensifier

EcoBoost for energy savings