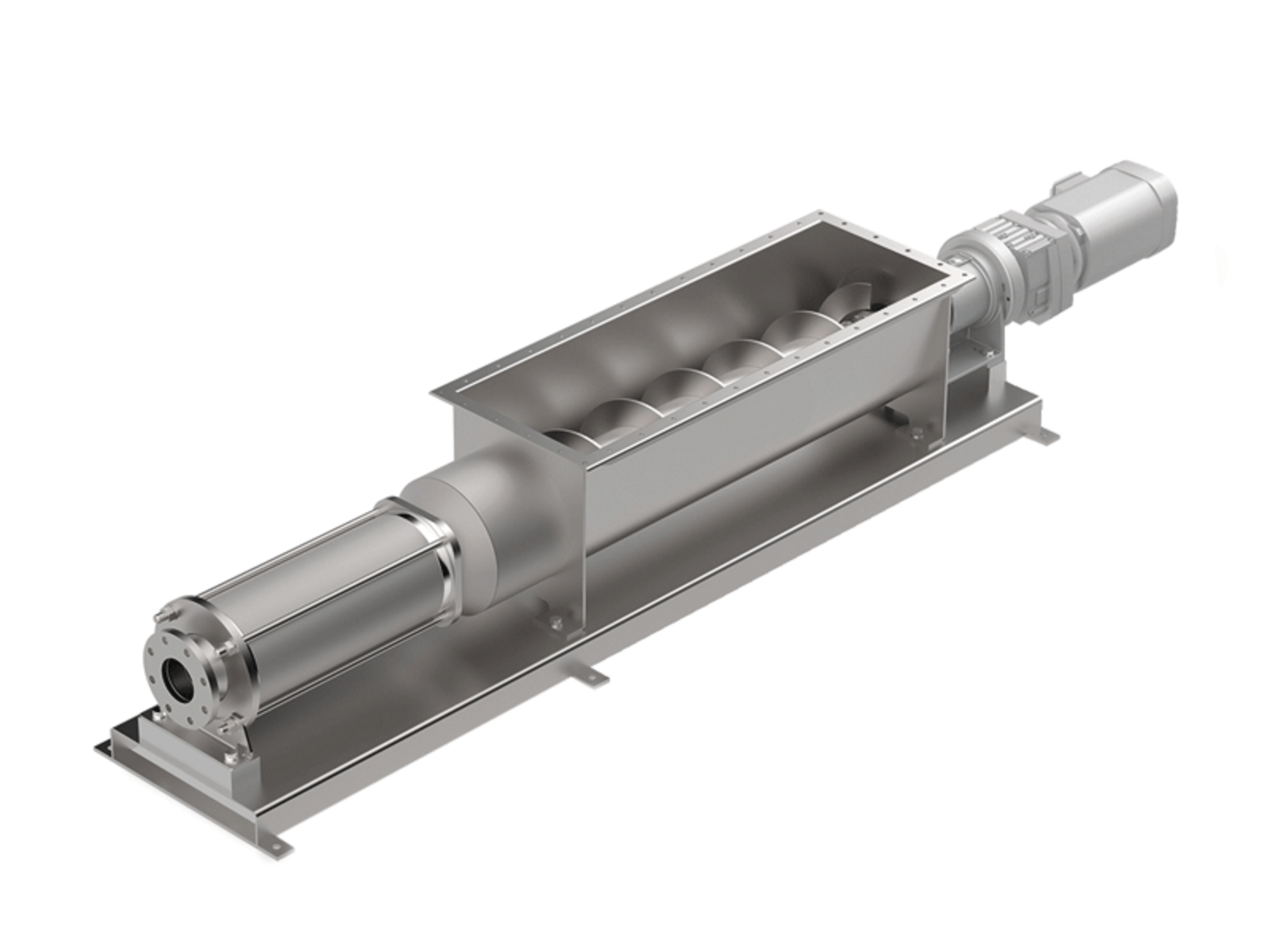

Hopper feed pump in hygiene design

General characteristics

- 0 to 150'000 l/h conveying capacity

- Pressures up to 48 bar

- For thin to compact media from approx. 0.3 to 8'000'000 mPas

- High dosing accuracy under harsh conditions

- Feeding through filling

- Large master hopper

- Suitable for bridging media

- Conveying of media with a high percentage of larger particles

- Up to pulsation-free volume flow

- Large adjustment ranges possible

- Gentle, low-shear conveyance {such as for whole fruits)

- The conveying quantity can be regulated in proportion to the dríve speed and remains relatively

- stable with changing pressures, temperatures and viscosities

General applications

- Dosing, conveying, emptying and reversing

- Up to abrasive, corrosive, gaseous and particle-laden media

Additional information

- Hygiene pump

- Plasticising pump v. fat blocks

- Pump with feed-assisting wheel

- Pump with return screw conveyor

- ATEX-conform pump available r

- Pump can be heated/cooled

- Pump with flap-hinge hopper